REQUEST A QUOTE

CONTACT US

ISO 9001:2015 Certified

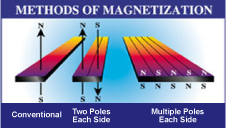

- conventional, one pole on each side

- two poles on each side

- multiple poles on each side

- custom magnitization patterns

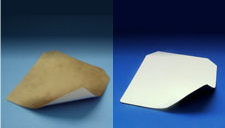

Adhesives from 3M Company and FLEXcon Company, Inc. are available in a variety of formulations to cover applications ranging from general purpose to automotive.

Adhesives come in the form of a thin film with a paper release liner and can be applied to our magnet material in the form of strips, rolls and die cut shapes.

Engineering, technical assistance and testing services are also available for the most demanding of applications.

Give us a call or drop us a note and see what Electrodyne can do for you.

Give us a call or drop us a note and see what Electrodyne can do for you.

Electrodyne offers vinyl lamination services where justified by the quantities purchased.

Give us a call or drop us a note and see what Electrodyne can do for you.

This service reduces the need for additional production operations on the part of the customer, and eliminates the problems associated with assemblies involving magnetized materials.

Often, prototyping services by Electrodyne can provide working models of the customer’s product, as many of Electrodyne’s products lend themselves to economical machining and forming processes.

Give us a call or drop us a note and see what Electrodyne can do for you.